Durability and Strength: The Advantages of Stainless Steel Strips

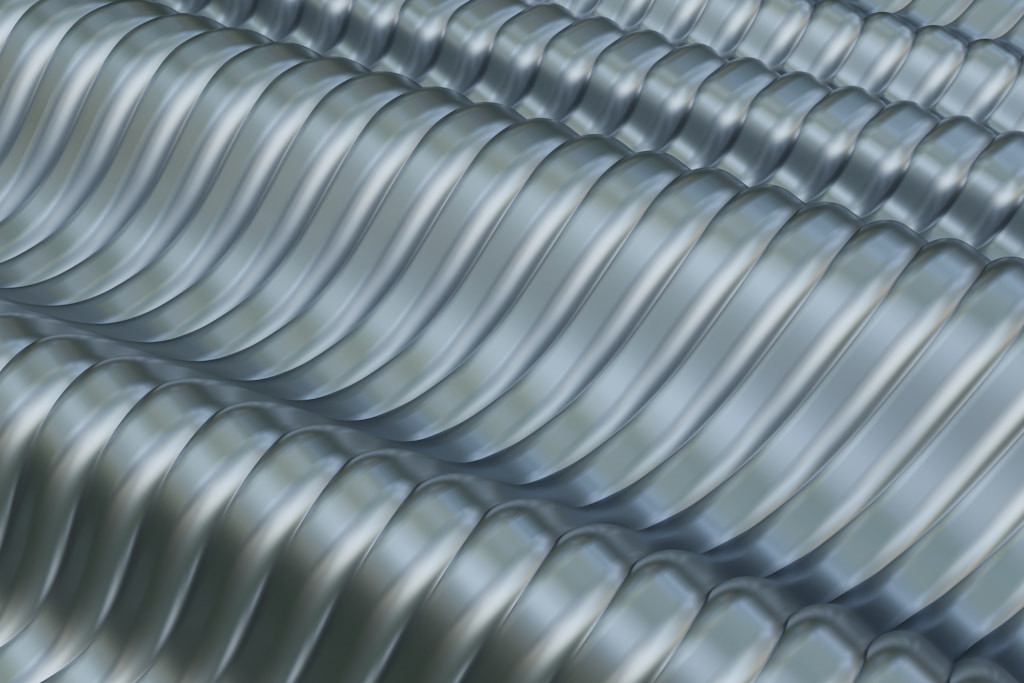

Stainless steel strips are a fundamental component in a wide range of industries, offering unmatched durability, resistance, and versatility. As a form of stainless steel characterized by its thin and elongated shape, stainless steel strips are commonly used in applications ranging from automotive parts to construction materials, household appliances, and even medical instruments. This article explores the inherent properties of stainless steel strips, focusing on their durability and strength and explaining why they are considered an optimal choice for numerous applications.

Superior Durability and Resistance

One of the primary advantages of stainless steel strips is their superior durability and resistance to various environmental factors. Stainless steel is renowned for its corrosion resistance, which is due to the presence of chromium in its composition. When exposed to oxygen, chromium forms a thin layer of chromium oxide on the surface of the steel, which serves as a protective barrier against corrosion. This self-repairing passive layer ensures that stainless steel strips retain their quality and appearance even when subjected to harsh conditions, such as exposure to moisture, chemicals, or salt.

Beyond corrosion resistance, stainless steel strips are also known for their resistance to high temperatures. Certain grades of stainless steel can withstand temperatures exceeding 800°C, making them ideal for use in heat exchangers, furnaces, and other high-temperature environments. The combined properties of corrosion resistance and heat resistance make stainless steel strips a versatile choice for many industries, providing long-lasting solutions that require minimal maintenance.

Exceptional Strength and Versatility

In addition to durability, stainless steel strips are highly valued for their exceptional strength. Depending on the grade and treatment, stainless steel can exhibit impressive tensile strength, which allows it to bear significant loads without deformation. This property makes stainless steel strips an excellent choice for structural applications, such as in the construction industry, where reliability and strength are critical.

The versatility of stainless steel strips is another key advantage. Available in various widths, thicknesses, and finishes, these strips can be tailored to meet the specific needs of different applications. Whether used for precision components in the automotive sector, reinforcing materials in construction, or the production of medical tools, stainless steel strips provide a reliable and flexible solution. Their adaptability also extends to manufacturing processes, as stainless steel strips can be easily formed, welded, and cut, allowing manufacturers to create custom components efficiently.

Sustainable and Cost-Effective Solution

Stainless steel strips are not only durable and strong but also represent a sustainable and cost-effective solution for many industries. Stainless steel is 100% recyclable, meaning that products made from stainless steel strips can be melted down and reused without a loss of quality. This characteristic reduces waste and minimizes the environmental impact of production, making stainless steel an environmentally responsible choice.

Moreover, while the initial cost of stainless steel strips may be higher compared to other materials, their long lifespan and minimal maintenance requirements contribute to significant cost savings over time. By choosing stainless steel strips, companies can benefit from reduced maintenance, fewer replacements, and ultimately lower overall costs.

For those looking for a reliable source of high-quality stainless steel strips, visiting https://rollsteel.eu/ can provide an overview of the available products and their applications. Rollsteel offers a comprehensive range of stainless steel strips tailored to meet the needs of various industries, ensuring both quality and versatility.

Applications Across Multiple Industries

The advantages of stainless steel strips make them a preferred material across numerous industries. In the automotive sector, stainless steel strips are used in the production of exhaust systems, chassis components, and other critical parts that require strength, durability, and resistance to high temperatures. In construction, stainless steel strips are utilized for cladding, structural reinforcements, and various other elements that demand a strong yet aesthetically pleasing material.

In the medical industry, stainless steel strips are used to produce surgical instruments, medical devices, and even implants, thanks to their biocompatibility and corrosion resistance. Meanwhile, in the food processing industry, stainless steel strips are employed in equipment such as conveyor belts, tanks, and mixers, where their hygienic properties and resistance to corrosion ensure safe and efficient operations.

The combination of durability, strength, versatility, and sustainability makes stainless steel strips an unparalleled material for a diverse range of applications. Whether in construction, automotive, medical, or food processing, stainless steel strips continue to be a reliable and high-performing solution that stands the test of time.